An Enterprise Contractor and Workforce Management Solution for a Global Mining Company

- Aug 23, 2019

- 4 min read

Updated: Aug 28, 2019

Here's how a global mining company identified 700+ unproductive work hours on day one of rolling out of an integrated Gallagher Access Control system, and how in excess of $1M per month in operational costs saving opportunities have been identified.

Background

Our client, a world leading mining company who operates mines and development projects worldwide, needed a system that could manage an extremely large contractor and employee workforce across various sites globally.

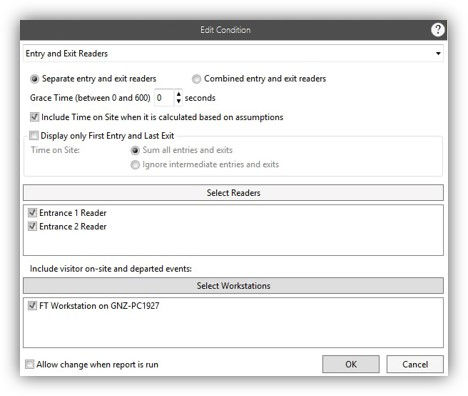

The client has keenly focused on the utilization of technology in enabling their growth and global expansion. The client uses Gallagher as their Enterprise Access Control product of choice, and selected FS-Systems as Systems Integrator for their global operations since 2013. The client manages contractor enrollment and inductions, permit issuing, and health and safety integrations for roughly 100,000 employees and contractors per year. Their operations are spread worldwide but they still maintain central visibility of all transactions recorded on the access control systems. An estimated 10 million+ access transactions are processed through biometric access credentials each year.

The Challenge

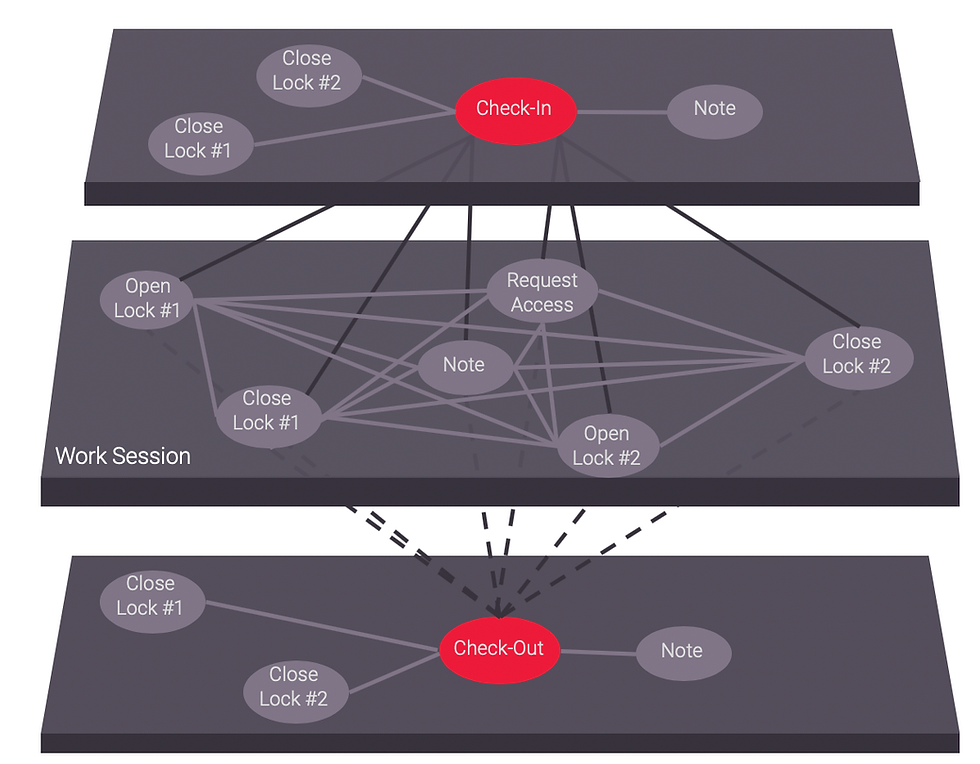

Efficiency and safety of all people on site was of critical importance. The technology solution deployed had to be robust and able to work in the harshest of environments. Huge ROI was possible if contractor billing could be matched with actual time worked on site. Enforcing of health and safety and compliance was of critical importance, as accidents and near misses could lead to mine shutdown and deep losses. Assurance of who is on site, if they were allowed on site, and what they did on site needed to be achieved.

The client was looking for a partner that had the required track record and experience in rolling out enterprise scale workforce management solutions; integrity and trust to be long term partner and support the solution for years to come; as well as a company that had a robust project management methodology enabling them to deliver projects in the most complex of environments.

FS-Systems complied to all set criteria and has formed a deep long-term relationship of trust with the client, protecting the lives of employees and contractors, and their critical assets through industry leading technology.

The Solution

FS-Systems leveraged deep experience in managing large scale access control projects in the educational and commercial space, and technical experience from 40+ years of operation. A challenge was to deep dive the real customer challenges and understand critical to success criteria of the project of this nature - for a global mining operation. Close collaboration happened between operations, engineering, health and safety, security, and IT departments. From the onset of the project a cross functional project team had to be established and managed.

FS-Systems see’s the detailed design and planning phase a key to the success of any project. The client was therefore actively involved in the technical design of the project and defining critical success factors associated with the project. From day one a clear ROI benchmark was set to be achieved by the technical solution. A project sponsor and champion was also put forward by the client to ensure dependencies on 3rd parties and internal stakeholders was well managed.

The project management methodology at FS-Systems is largely based on PM Bok, and therefore re-iterative feedback is collected at each major stage gate of the project. The project methodology further aims to provide real time visibility on issues, risks, quality and progress to all stakeholders. The client is therefore a partner in the project and is continuously updated on progress and roadblocks associated with the project execution.

On the first site that FS-Systems was asked to engage the client on, a Gallagher Enterprise Access Control system was rolled out, with full 1:1 Morpho biometric access control. The system had to cater for 30,000 contractors and employees that enter the site on a daily basis.

The installation comprised of:

150 full height biometric controlled access points;

20+ vehicle booms biometrically controlled;

Integration with Alcholizer for random H&S checks at each turnstile and boom;

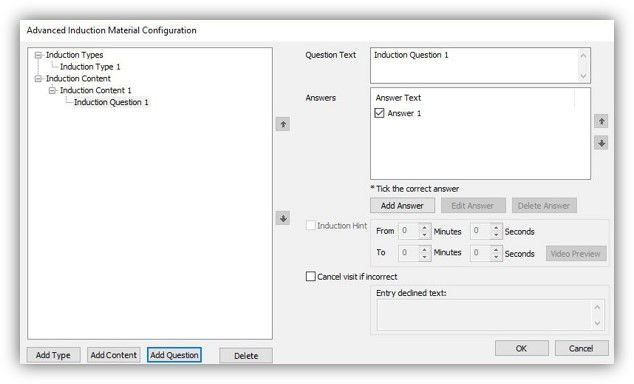

Visitor / contractor management with induction and permit issue integration;

System management of Competencies to restrict access to specific areas based on valid licenses, training, checks. Auto alert of expiry of competencies, training certificates and site-specific licenses;

Roll-out of Time & Attendance and integration to automated pay of contractors and employees in progress.

A similar installation was done on the second site, where critical production areas were brought on line and 20,000+ contractors and employees were enrolled on the Gallagher access control systems.

A third mine, as well as two offices in Africa are also running Gallagher access control, with global visibility and credential management across all sites.

Conclusion

Within day one of the roll-out a measurable ROI was achieved. 700+ unproductive work hours were identified within the first hour of the system going live.

Large inconsistencies between contractor billing and actuals time on site was also identified within the first month of operations, and the current estimate is that well in excess of $1m per month can be saved through further integration between Time & Attendance clocking of contractors and billing.

Safety has significantly increased on site, with real time control of alcohol testing and validity of licenses, training, and other competencies happening at the entrance point to the sites.

Comments